Capabilities

GIESE TECHNOLOGY

The Faro Probe

With the Quantum Max FaroArm, the world’s leading portable coordinate-measuring machine (CMM), we can capture every measurement of a complex part, tool or mold just by touching it

Whether it's machining or assembly, we can easily capture precise measurements on the shop floor and in the field, even in extreme temperatures.

Portable. Precise. Perfect.

GIESE TECHNOLOGY

Design/Improved Product Function

With more than a century in business, Giese has never stopped innovating. We continue to create, collaborate, and deliver innovative product experiences ... powerful product development solutions that open up new possibilities for our customers.

Smarter. Faster. Better.

GIESE TECHNOLOGY

Laser Welder

Bringing the efficiency of fully synchronized production to you with a cutting-edge, automated welding system.

Visually-pleasing seams. Faster. Better.

GIESE TECHNOLOGY

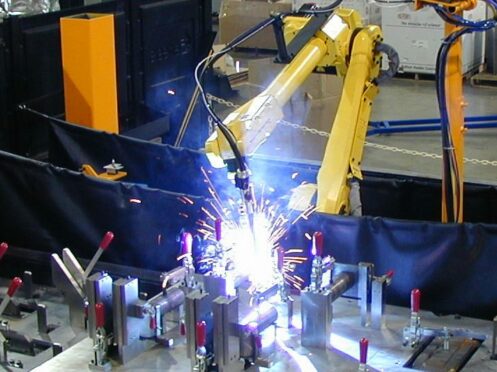

Robotic Welders

Robotic laser welding delivers precise and clean welds, contrasted with other methods of welding which are more prone to inconsistencies and may leave inaccurate welds.

Laser welding is also more versatile, working with a wide range of metal thicknesses. It can be faster than traditional welding and has a significantly smaller heat-affected zone, minimizing distortion of parts during welding.

Precise. Clean. Better.

GIESE TECHNOLOGY

Batch Powder Coating

Our Batch Powder Coating System enables Giese Powder-Coat Paint to efficiently powder coat and cure products in small- to medium-sized batch operations, ensuring high-quality finishes and increased throughput.

Following powder application, the part or product must be heated to a specific temperature for a set amount of time to ensure the coating is properly cured. Proper curing ensures a durable powder coating finish and a fully developed color.

Efficient. High-Quality. Durable.