Capabilities

Powder-Coat Paint

Giese Manufacturing’s new Powder Coat Paint Building helps to create a full service fabrication facility, with the customer’s need for a one-stop shop to take your project from idea to reality. We pride our work on handling the biggest jobs with ease and not losing sight of the small details with our long-time customers.

With our family of companies, we offer services and solutions that can take any project from concept to completion.

IT'S EASY WITH GIESE!

3-Stage Wash

Pre-Treatment System

Pretreatment is essential to ensuring powder or paint adheres properly to products.

Proper preparation of your product surface goes a long way in determining the quality of your finish.

Wash Booths and Industrial Pretreatment Washers lay the groundwork for consistent, quality finishes and prevent corrosion from forming on products.

Batch Powder Application Booth

Batch Powder Coating Systems enable businesses to efficiently prep, powder coat and cure products in small- to medium-sized batch operations, ensuring high-quality finishes and increased throughput.

Businesses can increase product quality and production rates.

Customers can benefit from utilizing the powder coat process with a streamline finish, high consistency and a real return on investment with end-user satisfaction.

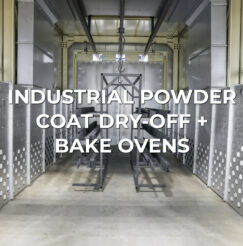

Industrial Powder Coat Dry-Off and Bake Ovens

These ovens feature excellent heat transfer technology, and ensure uniform temperature distribution for consistent, high-quality finishes.

Giese’s dry-off oven ensures that parts are free of any moisture and parts are prepped for powder in quick order after the pre-treatment wash process. Our bake oven provide shorter cycle times and increased throughput without compromising on quality.

Wet Paint Booth System

Giese’s Recirculating Paint Booth provides an accurate control of climate and airflow, while providing the most efficient operating system possible.

This booth is used in conjunction with temperature and humidity controls, regenerative thermal oxidizers and other VOC abatement equipment to provide a high quality standard of painting.