Capabilities

Precision Metal Fabrication

Giese Manufacturing is a full-service metal-fabrication company offering a wide range of state-of-the-art metal fabrication services to meet all production needs. From tractor and other machine components and cabinets to steel trusses and beams, stainless-steel sinks, industrial drains, and beyond, if it's made of metal, we can fabricate it.

With our family of companies, we offer services and solutions that can take any project from concept to completion.

IT'S EASY WITH GIESE!

Laser Welding

- Type: High-accuracy robot

- Number of Axes: 6

- Repeatability: +/- 0.05 mm

- Typical Maximum Part Size: 2000 mm x 1000 mm x 700mm

Robots, lasers, processing optics, enclosed protective housing, and positioners, the TruLaser Weld 5000 is a turn-key system for automatic laser welding. You can flexibly weld deep and strong seams or nicely rounded, smooth seams using one system. FusionLine also enables you to connect components with gaps. The versatile system can be precisely tailored to meet your needs with different component positioners.

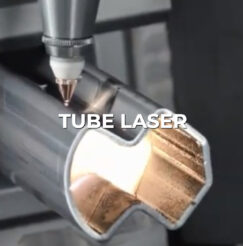

Tube Laser

Round, square, rectangle, special sections, and open profile tubes can all be used on this machine.

- Cutting Head: 3D tube cutter

- Tubes & Profiles: Up to 26 lb/ft in weight

- Tube Diameter: .472 to 9.45 inches

This BLM LT8.20 Tube Laser is the latest-and-greatest piece of technology at Giese Manufacturing.

Robotic Welding

One of our newest machines -- the Genesis Versa RC3L Robotic Welder -- takes productivity to an entirely new level.

Faster indexing times reduce overall weld-cycle time, and multiple robot configurations increase welding productivity.

With this machine, your projects can be produced more efficiently and more precisely than ever before.

Panel Bending

- Flexible: Universal tool for bending 11- to 27-gauge

- Productive: Automatic set-up in masked time

- Smart: Zero scrap and constant quality

- Force: Maximum bending force of 330 kN

- Versatile: Can make bends up to 135 degrees

Our Salvagnini® machine guarantees precision accuracy on every bend. It also makes an infinite number of bend types possible, ensuring higher levels of repeatability, safety, and productivity.

A machine like this allows us to produce quality products, and we can produce them faster than ever before.

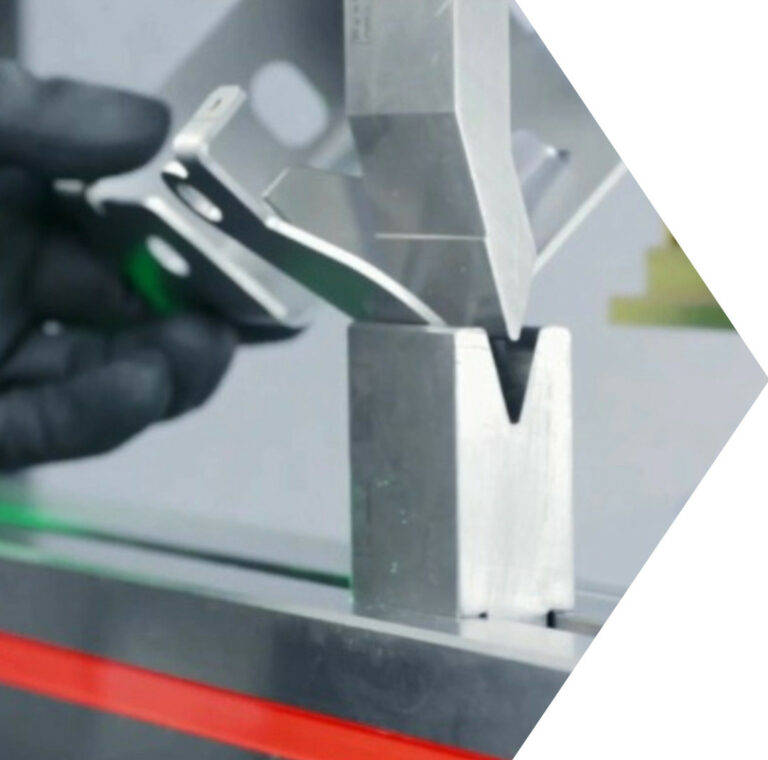

CNC Forming

- Tonnage: 40 ton

- Bending Length: 40.55

- Open Height: 22.45

- Max. High Speed: 11.8 in/s

- Max. Working Speed: 1in/s

Bending is a procedure for forming a flat, sheet metal workpiece. The workpiece lies on a bottom tool with a v-shaped opening. A wedge-shaped tool (punch) presses the workpiece into the v-opening and thus bends it to the desired angle. Our Bystronic Xpert press break gives us the perfect bend every time, ensuring your parts are always bent with the utmost precision.

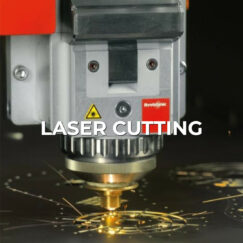

Laser Cutting

Our fiber lasers provide us a high level of production flexibility and almost unlimited diversity of materials and shapes. This is why lasers are viewed as an indispensable technology. We currently have four lasers and purchased our very first in 1999.

3015 BySprint 6,000 watt fiber - installed 2018

4020 BySprint 6,000 watt fiber - installed 2016

Material Thickness Range

- Stainless: .005" - 1.125"

- Aluminum: .005" - 1.125"

- Mild Steel: .010" - 1.00"

- Copper: .010" - 0.50"

- Brass: .010" - 0.625"

Maximum Sheet Size: 79" x 157"

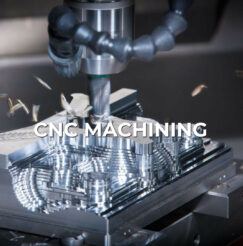

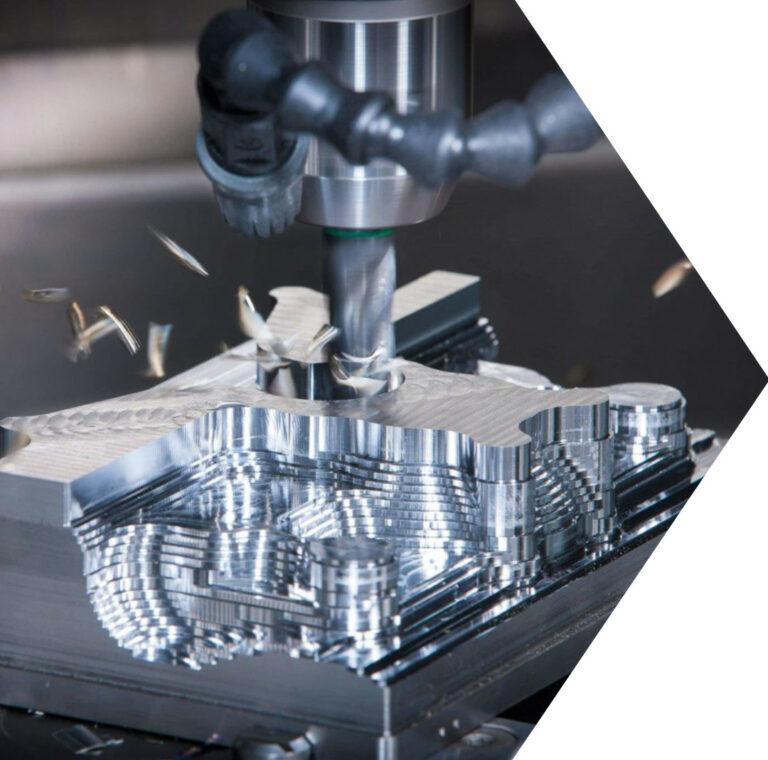

CNC Machining

Spindle

- Max Speed: 8,100 rpm

- Max Torque: 90 ft-lbf @ 2000rpm

- Power: 30 hp

Our Haas VF-5 machine, with its high-speed spindles, helps us produce an excellent finish while cutting down run times. It also allows us to be more accurate than ever. That means a high quality product built to your exact specifications every time.

CNC Drilling

- Max Beam Size: Accepts profiles up to 40". Max beam profile length 60ft & weight of 730 lbs/ft

- Max Drill Diameter: 2"

- Max Material Thickness: Up to 10"

- Max Speed: 120 ft per minute

- Drilling Speeds: 0-545 rpm

- Average Output: 200 to 400 holes per hour depending on profile being drilled

This Ocean Avenger® beam drill gets its outstanding drilling efficiency from the through-the-tool-coolant system. This system ensures the tool is always kept cool, even when drilling the thickest Jumbo beams or when drilling hardened steel. The coolant system also allows much faster drill feed rates than other machines.

CERTIFICATIONS